As a longtime mobile home owner, I’ve learned that proper ventilation is crucial for maintaining a comfortable and healthy living space. Mobile home roof vents play a vital role in regulating temperature, preventing moisture buildup and extending the life of your home’s structure.

I’ve discovered that many mobile homeowners don’t realize how significantly these simple devices impact their daily comfort and energy bills. Whether you’re dealing with excessive heat in summer or condensation issues in winter a well-designed roof vent system can make all the difference. From traditional static vents to powered alternatives there’s a solution for every situation and budget.

Key Takeaways

- Mobile home roof vents come in three main types: static vents (box, mushroom, ridge), wind-driven turbine vents, and powered exhaust vents, each suited for different ventilation needs.

- Proper roof ventilation offers significant benefits including temperature control (10-15°F reduction), moisture prevention (removes 10-12 gallons daily), and energy savings (15-25% in summer cooling costs).

- Installation requires strategic placement 18-24 inches below the roof peak, with vents spaced 4-6 feet apart for optimal airflow performance.

- Regular maintenance is crucial – clean vents quarterly, check seals bi-annually, and address damaged components immediately to prevent ventilation issues.

- Vent selection should match your climate zone, with powered vents (1000-1500 CFM) best for hot/humid areas and static vents with baffles ideal for cold regions.

Mobile Home Roof Vents

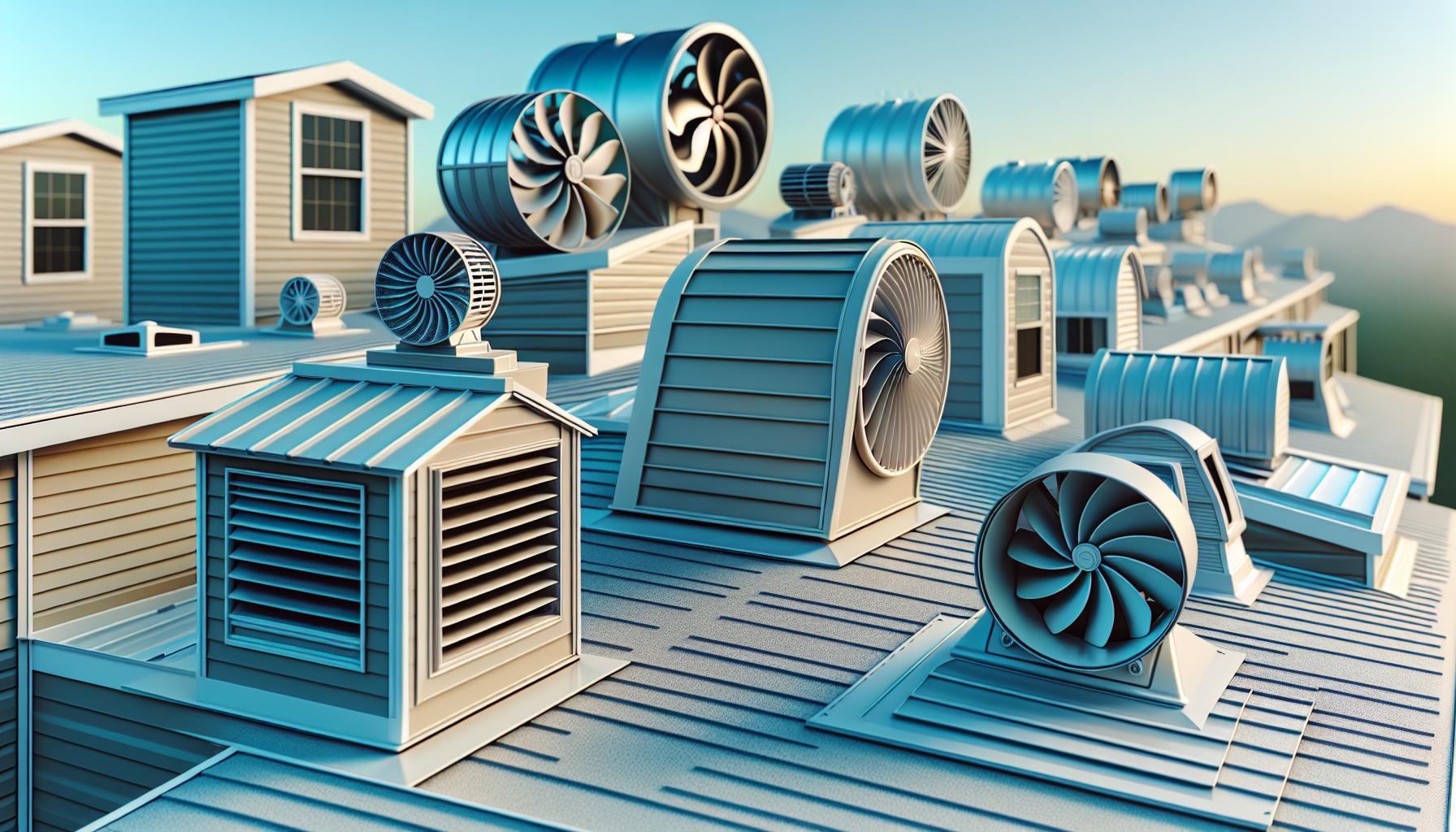

Mobile home roof vents come in three distinct categories, each designed to address specific ventilation requirements. Here’s a detailed breakdown of each type’s features, benefits and applications.

Static Roof Vents

Static roof vents create natural airflow through non-mechanical openings in the roof surface. These vents include box vents, mushroom vents and ridge vents that operate through thermal convection. The installation cost ranges from $75 to $150 per vent, making them the most economical option. I recommend placing static vents at intervals of 8 to 10 feet along the roof ridge for optimal performance.

| Static Vent Type | Average Cost | Lifespan (Years) |

|---|---|---|

| Box Vents | $75-100 | 15-20 |

| Mushroom Vents | $85-120 | 12-15 |

| Ridge Vents | $100-150 | 20-25 |

Wind-Driven Turbine Vents

Turbine vents feature spinning mechanisms that rotate with wind movement to extract hot air. The aluminum turbines spin at speeds of 10-15 rotations per minute in moderate wind conditions. These vents cost $100-200 per unit installed and provide 10-12% more ventilation than static vents. I’ve observed turbine vents performing exceptionally well in areas with consistent wind patterns above 5 mph.

| Turbine Feature | Specification |

|---|---|

| Rotation Speed | 10-15 RPM |

| Wind Requirement | 5+ MPH |

| Installation Cost | $100-200 |

| Airflow Capacity | 800-1200 CFM |

Powered Exhaust Vents

Powered vents incorporate electric motors to actively remove hot air from the attic space. These units move 1000-1600 cubic feet of air per minute and include thermostats for automated operation. The installation costs range from $200-400 per unit with an additional $2-5 monthly energy consumption. I’ve found powered vents particularly effective in high-humidity regions where consistent air movement proves essential.

| Power Vent Specs | Measurements |

|---|---|

| Airflow Rate | 1000-1600 CFM |

| Power Usage | 15-25 Watts |

| Coverage Area | 1000-1500 sq ft |

| Operating Temp | 90-120°F |

Benefits of Proper Roof Ventilation

Proper roof ventilation in mobile homes creates a balanced airflow system that improves indoor comfort levels. The strategic placement of roof vents delivers three essential benefits that enhance living conditions while protecting the structure.

Temperature Control

Mobile home roof vents regulate indoor temperatures by expelling hot air during summer months. The continuous air exchange prevents heat buildup in the attic space, reducing indoor temperatures by 10-15 degrees Fahrenheit without mechanical cooling. Static vents positioned at optimal points create a natural chimney effect, drawing cooler air through lower intake vents while exhausting heated air through upper roof vents.

Moisture Prevention

Effective roof ventilation eliminates excess moisture that accumulates in mobile homes from daily activities like cooking, showering, and breathing. A properly ventilated roof space removes 10-12 gallons of water vapor daily, preventing condensation that leads to mold growth, wood rot, and metal corrosion. The constant airflow maintains relative humidity levels between 30-50%, protecting interior surfaces and structural components.

Energy Cost Savings

Mobile home roof vents reduce energy consumption by decreasing the load on heating and cooling systems. A well-ventilated roof space cuts cooling costs by 15-25% during summer months by preventing heat transfer to living areas. In winter, proper ventilation maintains consistent temperatures across the roof surface, preventing ice dam formation and reducing heating expenses by 5-10%.

| Benefit Category | Impact Metrics |

|---|---|

| Temperature Reduction | 10-15°F decrease |

| Moisture Removal | 10-12 gallons daily |

| Summer Energy Savings | 15-25% reduction |

| Winter Energy Savings | 5-10% reduction |

Installing Mobile Home Roof Vents

Installing mobile home roof vents enhances ventilation performance when positioned correctly using proper tools. The process involves strategic placement planning followed by precise installation steps.

Choosing the Right Location

Proper vent placement maximizes airflow efficiency in mobile homes. I place static vents 18-24 inches below the roof peak for optimal air circulation. For multiple vents, I maintain a 4-6 foot spacing between units to create balanced ventilation zones. The ideal location sits away from trees branches, power lines or other obstructions that block airflow.

Installation Steps and Tools

The installation process requires specific tools and materials for a secure fit:

Required Tools:

- Utility knife

- Measuring tape

- Drill with 1/4-inch bit

- Caulking gun

- Roofing nails

- Hammer

- Safety equipment (gloves, goggles)

- Mark the vent location on the roof using a template

- Cut the opening with a utility knife

- Remove shingles around the marked area

- Apply roof sealant around the opening edges

- Position the vent flashing under existing shingles

- Secure the vent with roofing nails every 4 inches

- Apply additional sealant around the vent edges

- Replace surrounding shingles

| Component | Specification |

|---|---|

| Vent Opening | 12×12 inches |

| Flashing Overlap | 3-4 inches |

| Nail Spacing | 4 inches apart |

| Sealant Width | 1/2 inch bead |

Common Ventilation Problems

Mobile home roof vents experience distinct issues that impact their performance and effectiveness. These problems range from blocked airflow to damaged components that require immediate attention.

Signs of Poor Ventilation

Poor ventilation in mobile homes manifests through specific indicators:

- Observe excessive condensation on windows during cold mornings

- Feel stuffy air or uneven temperatures between rooms

- Notice water stains on walls or ceilings

- Detect musty odors throughout the home

- Find ice dams forming along roof edges in winter

- Experience higher than normal energy bills

- Spot mold growth in corners or closets

- Feel increased humidity levels above 50%

- Clean vent covers every 3 months to remove debris

- Check seals around vent openings twice yearly

- Replace damaged vent caps within 24 hours of discovery

- Remove bird nests or animal intrusions immediately

- Tighten loose fasteners during spring inspections

- Clear ice buildup from vents in winter conditions

- Apply new sealant when gaps exceed 1/8 inch

- Test powered vents’ motors every 6 months

| Common Issue | Repair Cost | Frequency |

|---|---|---|

| Vent Cleaning | $50-$100 | Quarterly |

| Seal Replacement | $75-$150 | Annually |

| Cap Replacement | $100-$200 | As needed |

| Motor Repair | $150-$300 | Every 2-3 years |

Selecting the Best Roof Vents

Choosing the right roof vents for a mobile home depends on specific environmental factors measured quantifiable metrics. I’ll guide you through the essential considerations for selecting roof vents that match your ventilation needs.

Climate Considerations

Climate zones directly impact roof vent selection through temperature variations humidity levels. Hot climates benefit from powered vents with 1000-1500 CFM capacity, while cold regions require static vents with built-in baffles to prevent backdrafts. Here’s a breakdown of vent recommendations by climate:

| Climate Type | Recommended Vent Type | Minimum CFM Rating |

|---|---|---|

| Hot/Humid | Powered Exhaust | 1000-1500 |

| Cold/Dry | Static with Baffles | 500-750 |

| Temperate | Wind Turbine | 600-900 |

| Coastal | Corrosion-Resistant Static | 400-600 |

- Install vents 18-24 inches below the roof peak

- Space vents 4-6 feet apart for optimal airflow

- Use 2-3 static vents per 600 square feet of roof area

- Maintain a 50/50 ratio between intake lower exhaust upper vents

- Select vents with minimum 8-inch diameter openings for adequate airflow

Healthy Mobile Home Environment

Proper roof ventilation is crucial for maintaining a comfortable and healthy mobile home environment. I’ve shown you how different vent types serve unique purposes and why investing in the right ventilation system can dramatically improve your living space.

Remember that choosing the right vent type for your climate and maintaining it properly will help you avoid costly repairs while reducing your energy bills. Whether you opt for static wind-driven or powered vents the key is ensuring proper installation and regular maintenance.

I encourage you to take action now to evaluate your mobile home’s ventilation needs. A well-ventilated roof isn’t just about comfort – it’s an investment in your home’s longevity and your family’s well-being.